car extrication device

This project aimed to reduce the cost of car extrication devices commonly used by emergency responders.

Through user interviews, our research revealed that these devices can impose a large cost on fire departments. Locally, only one station had one of these tools.

Our group prototyped a possible, low-cost solution to solve this issue. Using a DC motor, a 51:1 planetary gearbox, and a 3D printed polycarbonate housing, our design would bring the cost to hundreds of dollars instead of thousands.

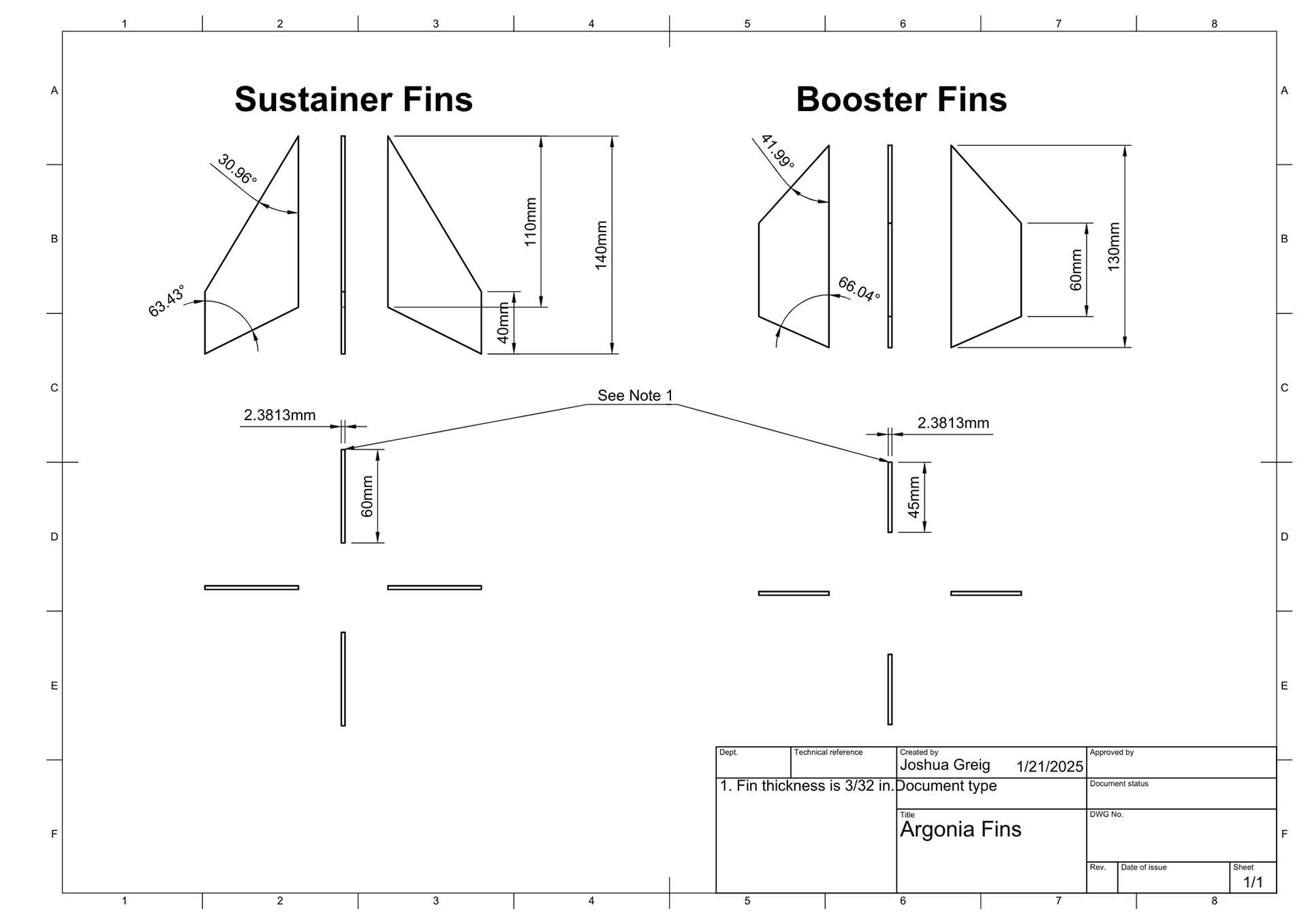

fin composite layup

I performed two-layer carbon fiber wet layups on the fins of our 2025 Argonia Cup rocketry team's vehicle. This process used a 3K carbon fiber fabric and industry-standard Aeropoxy resin. I also modified fin geometries using CAD software and exported the designs as DXF files for waterjet cutting.

Fin flutter can occur due to changes in air density at varying altitudes and the rocket’s velocity. In our case, the booster fins were the biggest concern during the initial phase of flight, and additional aerodynamic loads were expected on the sustainer fins as the rocket approached our projected top speed of Mach 1.7. The layers of carbon fiber were placed at 45 degrees, then 90 degrees relative to the longitudinal axis of the airframe. This increases the torsional and bending strength of each fin.